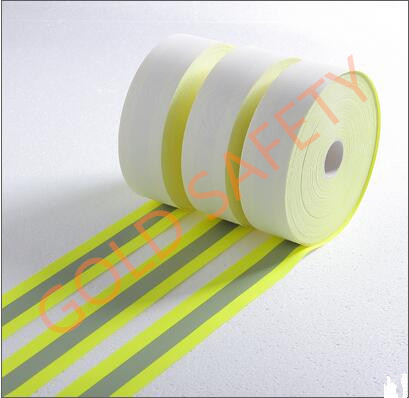

GS-1303-FR2Y

| Color | Yellow-silver-yellow |

| Backing Fabric | FR treated Cotton |

| Reflective Coefficient | R> 420 cd/lx.m2 |

| Washing Instruction | Home wash 50 cycles @ 60°C (ISO6330); Industrial wash 25 cycles @ 85°C (EN ISO 15797) |

| Certification | OEKO-TEX 100; EN 20471 Class 2; ANSI/ISEA 107-2010 Level 2; AS/NZS 1906.4-2010; CSA-Z96-02; EN 533; NFPA 701; ASTM F 1506 |

| Width | 2 or 3 inches |

| Packing | 50 meters/R |

| Delivery Time | 7 days after receiving payment or deposit |

| Departure Port | Ningbo or Shanghai |

| Supply Ability | 1,500,000 m²/ month |

| Flame Retardant Reflective Tape | ||||||||||||

| Product Number | Backing fabric | Initial Average R1 | Minimum R2 | Home Wash Cycles3 | Industrial Cleaning Cycles4 | EN 533 | NFPA701 | ASTMF 1506 | EN ISO 20471 | ANSI/ISEA 107-2010 | AS/NZS 1906.4-2010 | CSA-Z 96-02 |

| GS-1303-FR | FR treated cottonr | 420 | 330 | 50 | 25 | √ | √ | √ | √ | √ | √ | √ |

| GS-1303-FR2Y | FR treated cottonr | 420 | 330 | 50 | 25 | √ | √ | √ | √ | √ | √ | √ |

| GS-1303-FR2O | FR treated cottonr | 420 | 330 | 50 | 25 | √ | √ | √ | √ | √ | √ | √ |

| GS-1303-NM | 100% Aramid | 420 | 330 | 50 | 25 | √ | √ | √ | √ | √ | √ | √ |

| GS-1303-NM2Y | 100% Aramid | 420 | 330 | 50 | 25 | √ | √ | √ | √ | √ | √ | √ |

| GS-1303-NM2O | 100% Aramid | 420 | 330 | 50 | 25 | √ | √ | √ | √ | √ | √ | √ |

R1: Measured by Chinastars on new product at +5.0° entrance and 0.2° observation angles.

R2: ANSI/ISEA 107-2010 and EN ISO 20471 minimum coefficient of retroreflection for Level 2 retroreflective material.

3 Home wash according to ISO 6330 Method 2A at 60 °C and product maintain R ≥ 100 cd/lux/m3.

4 Industrial cleaning according to EN ISO 15797:2004 at 85°C and product maintain R ≥ 100 cd/lux/m3.

We supply quality reflective products for sporting activities, fire and rescue departments, law enforcement and first responders as well as hi vis industrial wear for construction and industrial application.

Our reflective fabric can be sewn on high visibility garment, sportwear, outdoor products: caps, bags, shoes etc. for road & utility workers, equipment operators, miners, and other professions where conspicuous visibility is critical to safety.

Most of our yellow FR reflective tape contains aluminum layer, and sweat /oil/ water stains may occur if the surface of the product has direct contact with hands during application and is then exposed to hot and humid conditions. Even though these blemishes won't affect performance of the product, we strongly recommend handling the reflective fabric with gloves and keeping them in the environment of below 26.7 °C (80 °F) and lowering than 70% relative humidity.

Some suggestions for extending the life of FR reflective tape on safety clothing:

1. When do machine wash, you may use a mild detergent, but No Bleach or Fabric Softener!

2. Try to avoid wash the reflective products with your work jeans or any clothing with rough fabric or edges. The microscopic glass beads on the retro reflective flame resistant tape can be worn off by rough texture.

3. Try to line dry your reflective products. If you choose to machine dry, try to remove the product immediately. The added heat can damage the flame resistant reflective tape.

| Copyright @ 2016 GOLD SAFETY MATERIAL CO.LTD. All Rights Reserved | Technical Support : AHWEBS |